Chassis Engineering: How to Maximize Torsional Rigidity for Better Performance

A rigid chassis provides the foundation for better performance, improved vehicle control, and increased safety. By minimizing flex, the suspension can effectively keep tires in contact with the road surface without interference from an unpredictable "fifth spring" effect created by chassis flex.

Race car chassis closeup view

Key Benefits of Chassis Rigidity:

- Better handling and cornering ability

- More predictable steering response

- Improved suspension performance

- Enhanced safety and vehicle control

- Reduced squeaks and vibrations

Racing car crashes into wall

Modern vehicles use unibody design, where the body shell serves as the frame and structure. Each new generation typically offers increased chassis rigidity through improved computer modeling, metallurgy, and manufacturing techniques.

Practical Ways to Increase Chassis Rigidity:

- Bolt-on Solutions:

- Strut tower braces

- Under-chassis braces

- Sub-frame braces

- Lower tie bars

- Fender braces

- Race-Specific Solutions:

- Weld-in roll cages

- Stitch welding

- Chassis seam riveting

Race car chassis side view

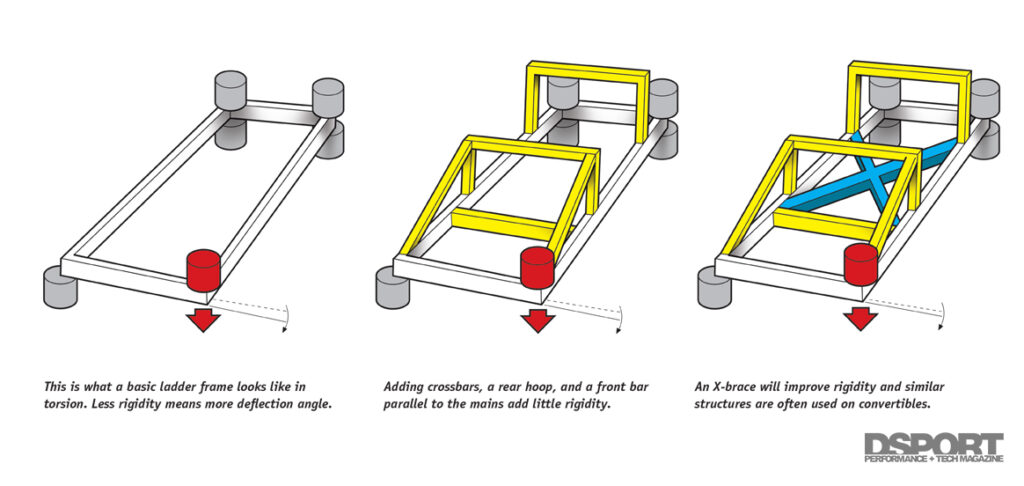

The Triangle Principle: Triangle geometry provides maximum rigidity with minimal weight, making it the preferred structure in both racing and street applications.

Torsional Rigidity Measurements:

- 1966 Ford Mustang: ~5,000 Nm/degree

- 2015 Ford Mustang: >20,000 Nm/degree

- Bugatti Veyron: >60,000 Nm/degree

Note: Convertibles typically have about half the torsional rigidity of their coupe counterparts due to the missing roof structure.

Chassis diagram with labeled components

Improving Chassis Rigidity:

Street Applications:

- Use triangulated front strut tower braces (10% improvement)

- Install X-pattern lower front bracing

- Add rear strut tower braces when possible

Race Applications:

- Install properly designed weld-in roll cage

- Perform strategic stitch welding

- Add chassis reinforcement in critical areas

For optimal results, address the chassis as three sections:

- Front (up to firewall)

- Center (firewall to rear seats)

- Rear (rear seats to end)

Remember: While chassis rigidity improvements may not show on a dyno, they can be felt in driving dynamics and verified on timed road courses. The goal is maximum rigidity with minimum weight addition.

Car chassis with wheels mounted