DIY Powder Coating: A Beginner's Guide to Professional-Grade Finishes

Let me provide a concise, valuable rewrite focusing on practical DIY powder coating information:

Powder coating offers a durable, professional-quality finish that DIY enthusiasts can achieve at home with the right equipment and technique. This guide covers everything you need to know to get started.

Black and silver Brembo caliper

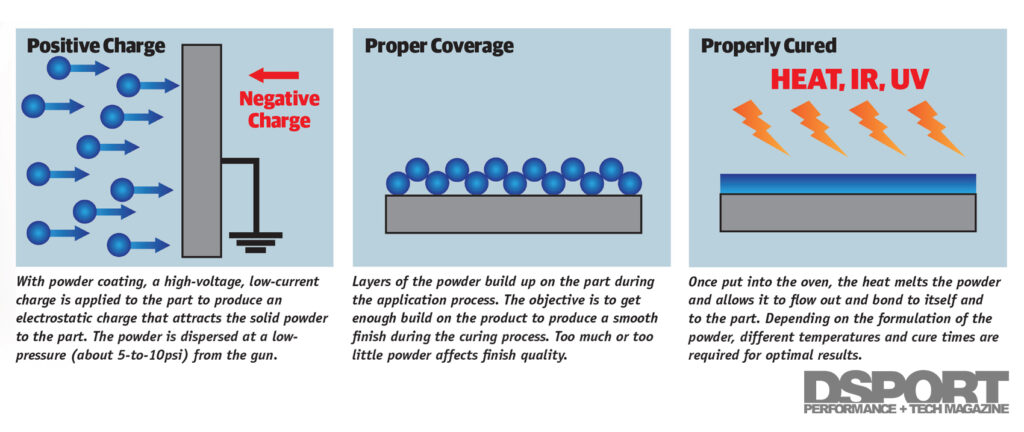

What is Powder Coating?

Powder coating uses electrostatically-charged powder that melts and cures into a durable finish when heated. Unlike liquid paint, powder coating:

- Provides thicker, more durable coverage

- Resists chemicals and scratches better

- Creates fewer runs and sags

- Works regardless of ambient temperature

- Allows easier multi-stage finishes

Required Equipment:

- Electric oven (dedicated for powder coating)

- Powder coating gun ($75-130)

- Air compressor

- Infrared temperature gun

- Timer

- Surface prep materials

- Proper safety equipment (mask, gloves)

Three powder coating bottles

Basic Process:

- Surface Preparation:

- Strip old finishes completely

- Clean thoroughly with acetone

- Pre-bake part at 400°F to remove contaminants

- Cool and wipe again with acetone

- Application:

- Apply powder generously

- Use proper voltage setting

- Ensure even coverage

- Build adequate thickness

- Curing:

- Monitor surface temperature carefully

- Follow manufacturer's temperature specifications

- Maintain proper cure time

- Allow to cool completely

Powder coating diagram with process steps

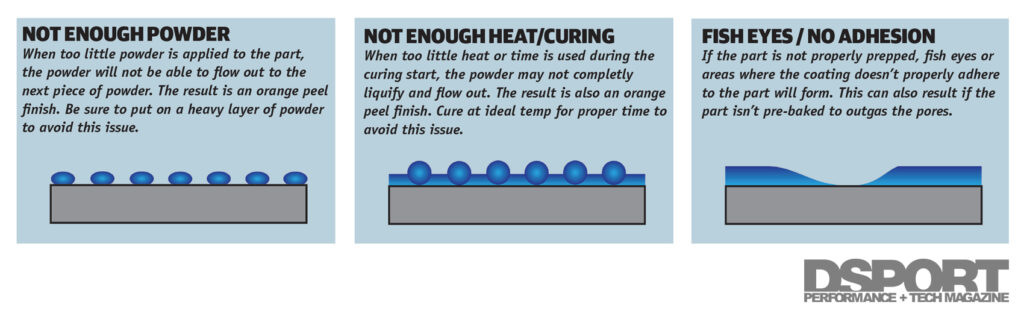

Common Issues and Solutions:

- Poor Adhesion: Inadequate surface prep

- Orange Peel: Insufficient powder application

- Bubbling: Excessive temperature

- Yellow Clear Coat: Overbaking

- Uneven Finish: Inconsistent application

Cost Considerations:

- Basic setup: $200-300

- Powder cost: $10-30 per pound

- More economical than quality spray paint long-term

Powder coating issues and solutions diagram

Safety Precautions:

- Always wear proper respiratory protection

- Use dedicated oven (never use kitchen oven)

- Monitor temperatures carefully

- Handle hot parts with appropriate tools

- Ensure proper ventilation

With proper preparation and attention to detail, powder coating is a viable DIY option that produces professional-quality results. While there's a learning curve, the durability and finish quality make it worth the investment for enthusiasts who regularly finish parts.

Related Articles

A Street Car Named Desire: Inside Chris Phan's GT3-Inspired Nissan GT-R Build