Toyota Deliberately Crashes GR Models to Ensure Perfect Performance

Toyota's rigorous GR testing methodology combines intensive track testing with precision manufacturing to create consistently high-performance vehicles. At their Gazoo Racing facility in Japan, development drivers including Toyota Chairman Akiyo Toyoda (racing alias "Morizo") deliberately push test vehicles to their limits until failure.

Toyota GR Yaris factory tour

This destructive testing has led to critical improvements. For example, when Morizo rolled a GR Yaris due to a four-wheel drive system fault, engineers identified and fixed the software issue before it could affect production vehicles.

Toyota GR Yaris drifting on gravel

Toyota GR Yaris rolled on track

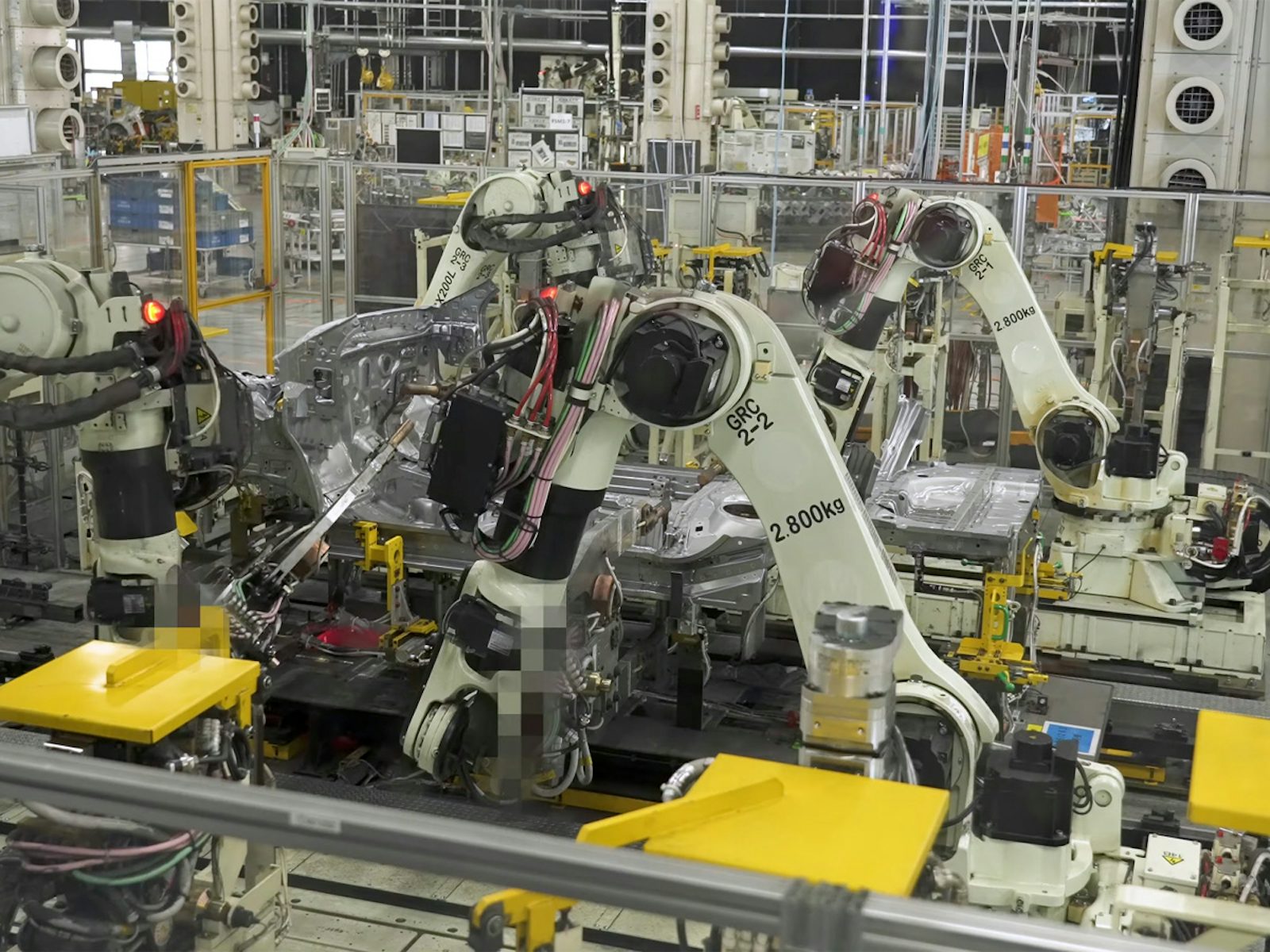

The GR factory employs a unique cell-based assembly process, more akin to motorsport operations than traditional production lines. This allows for rapid implementation of improvements while maintaining exceptional precision.

Toyota GR Yaris bodyshell

Key manufacturing features include:

- Ultra-tight tolerances far exceeding standard production cars

- Precise measurement of suspension mounting points

- Custom-matched subframes for each vehicle

- Steering wheel remains untouched until final alignment

- Usage of turntables to avoid premature steering forces

Toyota GR Yaris on production line

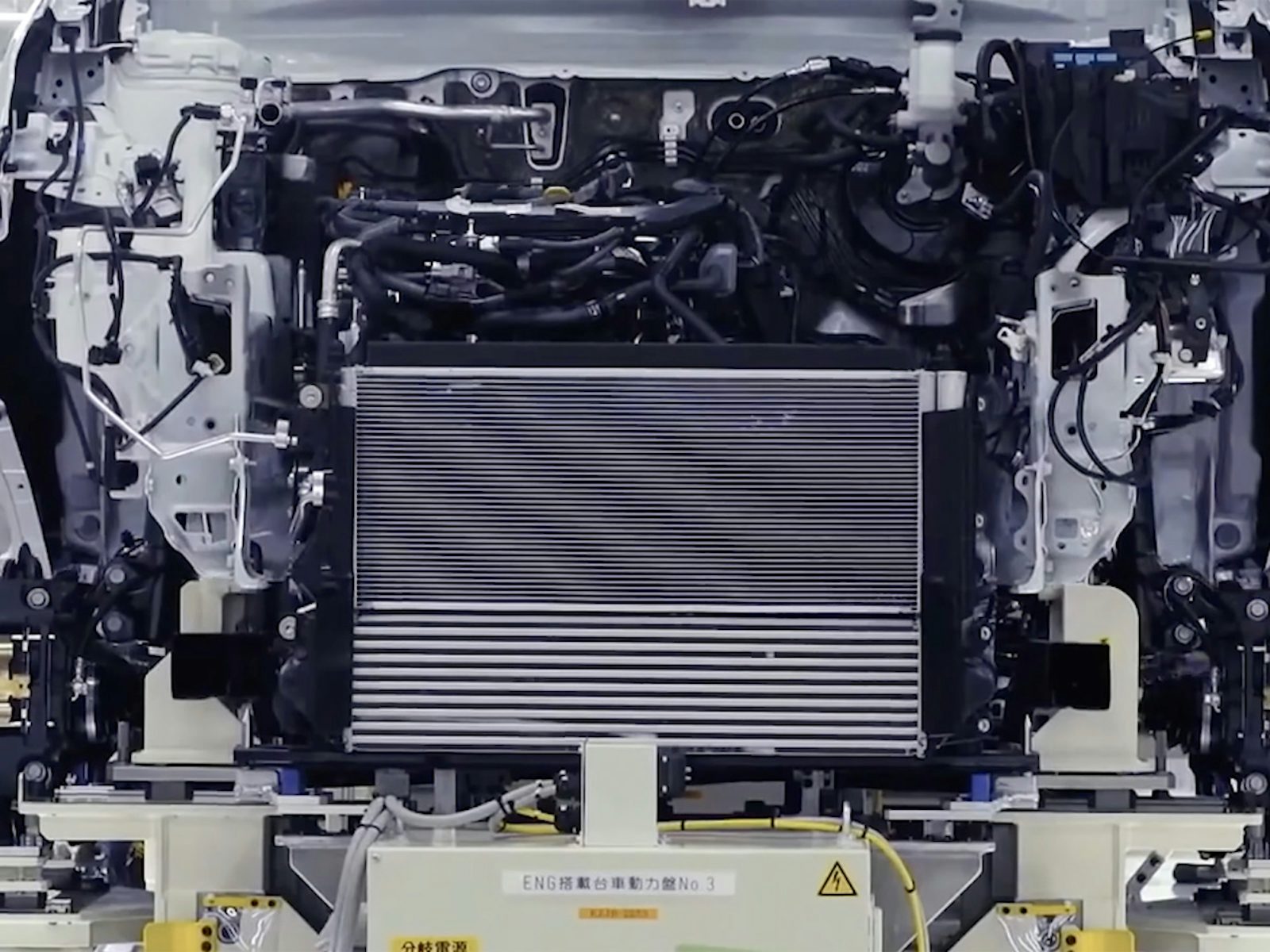

GR Yaris turbocharged engine bay

Each GR vehicle undergoes thorough testing post-production, including aggressive steering and brake testing, ensuring identical performance across all units produced.

White Toyota GR Yaris sports car

Side view Toyota Yaris white

This commitment to excellence through destructive testing and precise manufacturing has resulted in consistently high-performing vehicles that meet Toyota's exacting standards for their performance line.